Revolutionizing Uniform Laundry Industry Through RFID Integration

The inception of RFID technology marked a pivotal turning point in the uniform laundry sector. In its early adoption, the industrial laundry domain exclusively embraced high-frequency (13.56MHz) RFID technology. Central to this innovation was the RFID platform, comprising an RFID reader and an array of antennas. Sewn directly onto clothing, RFID tags became the cornerstone of efficient uniform and garment processing. Each labeled attire traversed various processing stages, with the RFID tags facilitating seamless tracking through laundry equipment. These reading points found strategic placement across reception, sorting, washing, drying, ironing, folding, sorting, and distribution areas.

A critical criterion for these RFID labels was durability in the face of cleansing chemicals and the intense temperatures of laundering, drying, and ironing. The longevity of these tags had to surpass the lifespan of the clothing items themselves.

Enter the Evolution of UHF RFID Uniform Tags

December 2004 witnessed the certification of a game-changing RFID standard: EPC Gen 2. This paradigm shift ushered in transformations in RFID functionality and pricing. Contrasted with high-frequency tags, Gen 2 RFID tags boasted the advantages of cost-effectiveness and extended read ranges, spanning from centimeters to meters.

The conventional methods of uniform management became inadequate for the meticulous demands of the industry. The rise of RFID technology brought forth unprecedented prospects for the uniform rental sector. The lion’s share of the emerging laundry industry embraced this cutting-edge facet of RFID technology.

The Transition to UHF RFID Uniform Tags

Previously confined to low-frequency and high-frequency domains, the landscape has progressively welcomed UHF RFID technology. Its attributes of extended reading distances, capacity to scan multiple tags simultaneously, and memory expansion have augmented its appeal. The application of UHF uniform tags encompasses versatile attachment methods. These tags can be sewn in disc/button or rectangular configurations, affixed using industrial-grade adhesives, or employed as hang tags.

JYL-Tech’s Stride in UHF RFID Smart Linen Tags

JYL-Tech’s UHF RFID smart linen tag emerges as a trailblazing solution. Resilient and washable, this tag endures over 200 industrial wash cycles. Weathering the rigors of industrial and medical laundering, it thrives under 60-bar atmospheric pressure, ensuring steadfast and dependable performance.

Boasting a lifespan exceeding 200 industrial washes, backed by a flawless memory write test record, validated material and design reliability, and ATP EECC certification, this tag transcends industry standards. Its applications span RFID industrial washing, RFID linen rentals, RFID uniform management, and beyond. The infusion of RFID technology establishes an agile platform for swift collection, sorting, automated inventory, and streamlined linen management within the uniform rental sector.

Anticipated outcomes encompass elevated management efficiency, precision, and cost-effectiveness. The era of automated and refined uniform rental management is now within reach, promising error reduction, lowered operational costs, and the pinnacle of automation and precision management.

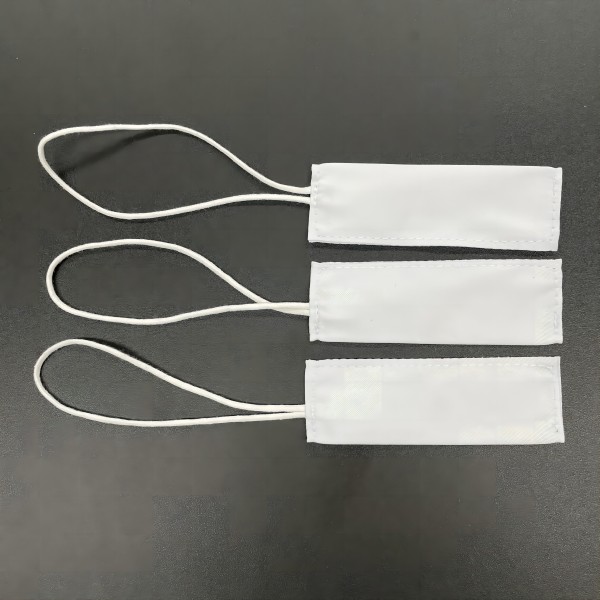

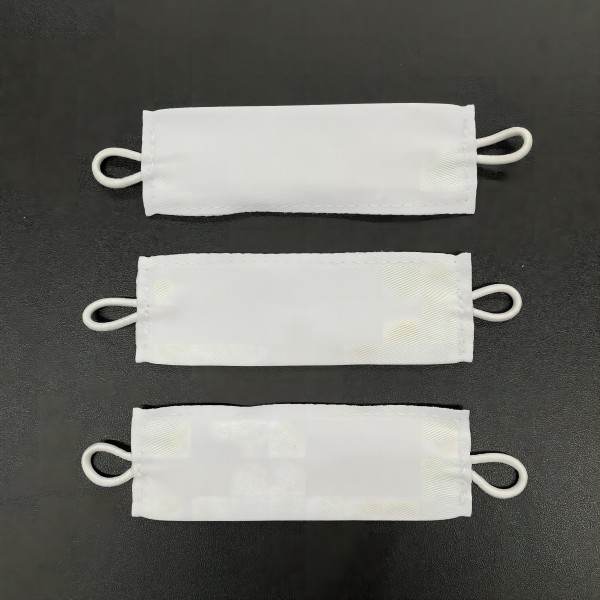

New Detachable RFID Linen Tag for Uniform Management :

|  |

| Detachable RFID Linen Tag | Detachable RFID Linen Tag |

| UHF EPC Class1 Gen2 | UHF EPC Class1 Gen2 |

| 82*28mm | 82*28mm |

| Pouch and Strap | Pouch and Elastic Strap |

Related Products

Contact Form

We can help you?

Share this page